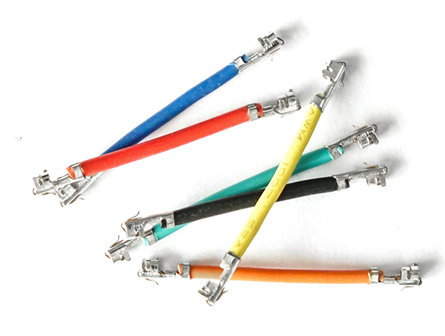

Processed Samples:

| Product Parameters | |

| Product Model | CM-S01-06 |

| Product Name | Fully Automatic Double-head Terminal Machine-Mitsubishi Servo Model |

| Product Features | Automatic wire cutting, stripping, double-ended crimping terminals |

| Ultra high precision model | |

| Peeling Range | 0.5-35MM (over 12MM, half stripped is required) |

| Cutting Line Tolerance | When the wire length is ≥1000MM, ±0.4%. The longer/thicker the wire, the greater the tolerance |

| Processing Length | 26-9900MM (Customized with 14MM rubber left) |

| Crimping Force | Standard 2T30 stroke (optional 3T)/(optional 40 stroke) |

| Wire Adaption | AWG18-32# 1007 Single electronic wire |

| Applicable Mold | OTP card mode (Flag-shaped/European-style mode) |

| Electrical Support | AC 220V 2.5Kw Air: 0.4-0.6MPa |

| Equipment Size | Length 1380*Width 750*1580 Height MM / 360KG |

| Processing Capacity | Within 300MM, 4800-5200PCS/H |

| Machine Configuration | |

| Pneumatic Component | AirTAC Pneumatic |

| Linear Slide | 7 Sets Hiwin Guide Rails |

| Ball Screw Rod | 4 Sets TBI Screws |

| Crimp Motor | 0.75KW Three-phase Asynchronous Motor, Frequency Conversion Control (Optional 1.5KW/2.2KW) |

| Action Motor | 5 Sets Mitsubishi Servo, 2 Sets Xuquan Stepper |

| Touch Control | 7-inch Xinje Color LCD with Touch |

| Drive Control | Jiayuan Intelligence |

| Motor Frequency Conversion | Jiayuan Intelligence |

| Circuit Control | Chint Electrical Appliances |

| Program Control | PLC Control |

| Optional Accessories | Automatic pay-off reel, conveyor belt, pressure monitoring, visual inspection |

| Detection Function | Terminal Detection Include Air Pressure Detection Include Wire Detection Include |

| Fault Alarm Include Pressure Monitoring (Optional) | |

Our friendly team would love to hear from you!